-

Tail Light 1 x $80.00

Tail Light 1 x $80.00 -

Wiper Blades 1 x $80.00

Wiper Blades 1 x $80.00 -

Suspension 1 x $80.00

Suspension 1 x $80.00 -

Air Filter 1 x $80.00

Air Filter 1 x $80.00 -

Car Brakes 1 x $80.00

Car Brakes 1 x $80.00

Overview

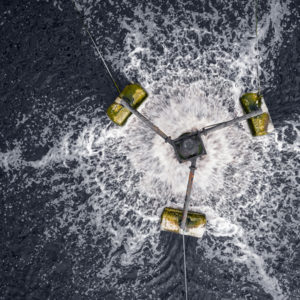

Water treatment plants, as you know, make the not-so-clean water appropriate for a specific end-use like drinking, industrial water supply, irrigation, recreation or, farming.

There are numerous physical, chemical, and biological processes used in your average WTPs. Where we come in is to understand your specific needs and the end usage of the treated water and design a water treatment solution to that.